CS-9813C is an addition molding medium temperature curing silicone sealant, which is a specialized sealant for G9 halogen lamp sealant silicone corn lamp, G4/G9 and other products. After gel curing, it has good elasticity, high and low temperature resistance, strong adhesion, no cracking, no hardening, high transmittance, good thermal stability, low stress, and low moisture absorption.

※ Usage and precautions:

1. Mix the adhesive of components A and B evenly in a 1:1 weight ratio; (When mixing glue, it is important to ensure that no other impurities are introduced, and it is best to use clean specialized containers and mixing rods);

2. Put the mixed glue into the defoaming device for defoaming, and seal it after the bubbles are completely removed; Due to the low surface tension of silicone gel, it is easy for the gel to overflow from the container during the defoaming process. Therefore, it is best to use a container with four times the volume of the gel or to use the intermittent defoaming method for defoaming. That is, after 10 seconds of vacuum accumulation, quickly turn off the vacuum machine to restore normal pressure. After repeating this process several times, the bubbles can be emptied of the gel without overflowing the container;

3. Pour the defoamed glue into a dedicated mold, and after sealing, bake it at 90 ℃ for 1 hour. Then raise the temperature to 120 ℃ and bake it for 1 hour. After the glue is completely cured, let it cool naturally to room temperature before proceeding with subsequent operations;

Attention: The entire operation is recommended to be carried out in a dry and dust-free environment.

※ Special Reminder

Unused adhesive should be stored in a sealed container. The storage period is 10 months (25 ℃). The mixed adhesive should be used up at once to avoid waste.

This product is non hazardous, but should not be ingested or seen.

Transportation: There are no regulations for domestic (CN-GB) or international (IMO, IATA, UN) transportation. Belonging to non dangerous goods.

The adhesive solution may experience poisoning when exposed to the following chemicals (trace amounts of the following substances will not affect curing): (Poisoning: The adhesive cannot cure)

·N. Organic compounds P and S.

·Ionic compounds of elements such as Sn, Pb, Hg, As, etc.

·Containing alkynes and multi vinyl compounds.

·To avoid the above phenomenon, try to wipe off the residual rosin on the circuit board as much as possible and use solder with low lead content.

characteristic:

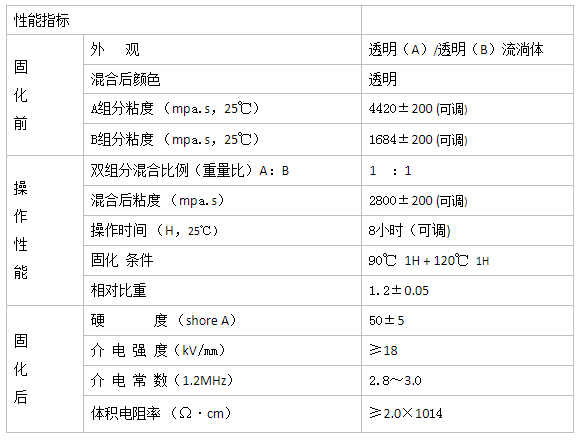

Both components A and B of this product are transparent viscous liquids, which can be stored for a long time before mixing;

It has excellent high and low temperature resistance and can be used normally within the range of (-40~280 ℃);

Has excellent adhesion, with good adhesion to PCB and most metals;

Has excellent transmittance and refractive index, transmittance>96%, refractive index>1.41;

It has the characteristics of low stress and low moisture absorption, which can greatly ensure the stability of the lighting after sealing.

Mobile website

Mobile website WeChat official account

WeChat official account