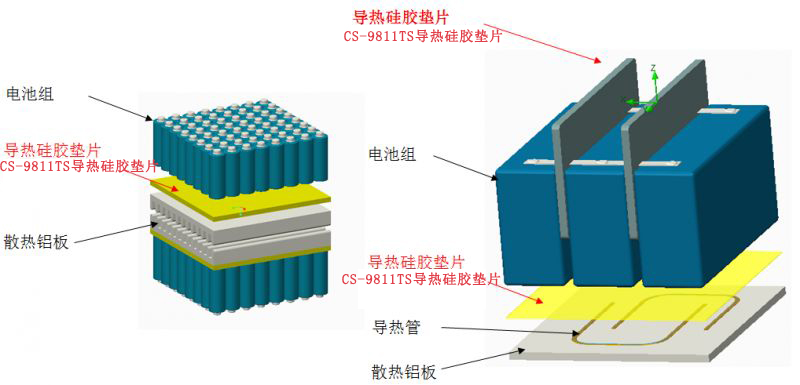

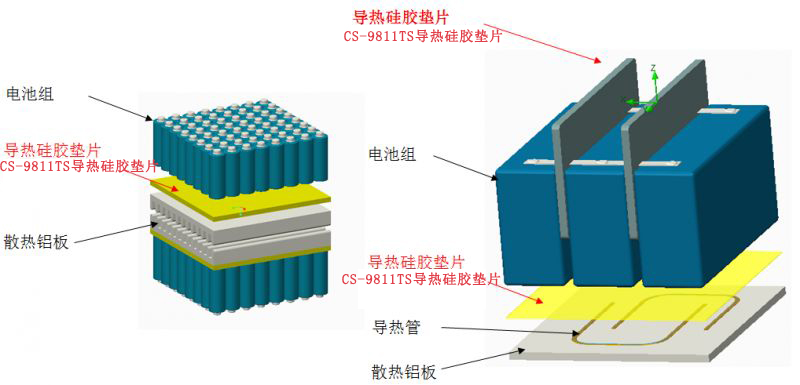

The CS-9811TS thermal conductive silicone sheet series features a special ultra-thin fiberglass cloth double-layer structure, which increases operability and tensile strength. It is also resistant to damage in continuous sports environments and has a service life of over 15 years.

Widely used in industries such as LED lighting, automotive electronics, televisions, power supplies, communication products, and network products.

Widely used in industries such as LED lighting, automotive electronics, televisions, power supplies, communication products, and network products.

Usage and precautions:

1. Keep the contact surface with the thermal conductive silicone sheet clean to prevent the thermal conductive silicone sheet from sticking to dirt. The self adhesion and sealing thermal conductivity of the dirty thermal conductive silicone sheet will deteriorate.

When picking up the thermal conductive silicone film, the larger area of the film should be grasped from the center, and the smaller area of the film is not required to be grasped, because large pieces of thermal conductive silicone film are subjected to uneven stress, which can cause deformation, affect subsequent operations, and even damage the silicone film.

3. Hold the sheet with your left hand and tear off one side of the release protective film with your right hand. It is not allowed to tear off both sides of the protective film at the same time to reduce the number and area of direct contact with the thermal conductive silicone film, and to maintain the self-adhesive and thermal conductivity of the thermal conductive silicone film without damage.

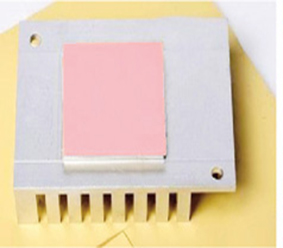

4. Tear off one side of the protective film, facing towards the heat sink, and align the thermal conductive silicone film with the heat sink first. Slowly lower the thermal conductive silicone sheet. Be careful to avoid the formation of bubbles.

5. If bubbles are generated during operation, pull up one end of the silicone film and repeat the above steps, or gently wipe off the bubbles with a tool, without excessive force, to avoid damage to the thermal conductive silicone film.

6. Remove the protective film on the other side and place it in the radiator. The force of removing the last protective film should be small to avoid pulling or damaging the thermal conductive silicone sheet.

7. After tightening or using a strong adhesive thermal conductive silicone film, apply a certain pressure to the radiator and store it for a period of time to ensure that the thermal conductive silicone film is fixed properly.

Mobile website

Mobile website WeChat official account

WeChat official account