It is mainly composed of adhesive and heat conducting particles. Before sizing, it is a paste like mixture. After sizing, it solidifies under certain time and conditions. Our heat-conducting silica gel is a one component room temperature vulcanized silicone rubber, which has a good bonding effect. Room temperature curing, simple curing conditions, repairable, curing thickness generally between 4-5mm. However, it is sensitive to the surface state of the radiator, and the binding force of the surface polluted device or radiator is weak. Strict on-site process control.

1. Environmental protection, non-toxic, non corrosive, in line with RoHS and reach instructions.

2. Excellent adhesion, fixation, insulation, sealing, moisture-proof, shockproof and aging resistance.

3. It can be firmly bonded with metal, glass, ceramic, plastic and other materials.

4. The cured silicone rubber has good electrical insulation performance, high and low temperature resistance, water and moisture resistance, aging resistance and long-term rubber elasticity.

performance index

Before curing: ① external view: white half flow; ② product type: condensation type; ③ viscosity; MPa. S, 25 ℃): 30000-50000 & nbsp; ④ relative specific gravity (25 ℃): 1.55 & plusmn; 0.05

Operating performance: ① surface skinning time (min, 25 ℃): 10-30 & nbsp; ② curing time & nbsp; (min, 25 ℃): 8-12 hours (3-5mm) ③ curing time (min, 80 ℃)

After curing: ① hard (Shore A): 55-65 & nbsp; ② thermal conductivity [& nbsp; w (M & middot; K): & Ge; 0.6 & nbsp; ③ dielectric strength (kV / mm): & Ge; 15 ④ dielectric constant (100MHz): 3.0

&Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; ⑤ volume resistivity & nbsp; (& omega; & middot; cm): & Ge; 1.0 & times; 1015 & nbsp; ⑥ elongation at break (%): 120-150 & nbsp; ⑦ temperature range (℃): 60 ℃ - 200 ℃

&Nbsp; 1.0 & times; 10-3 & nbsp; ⑦ flame retardant rating

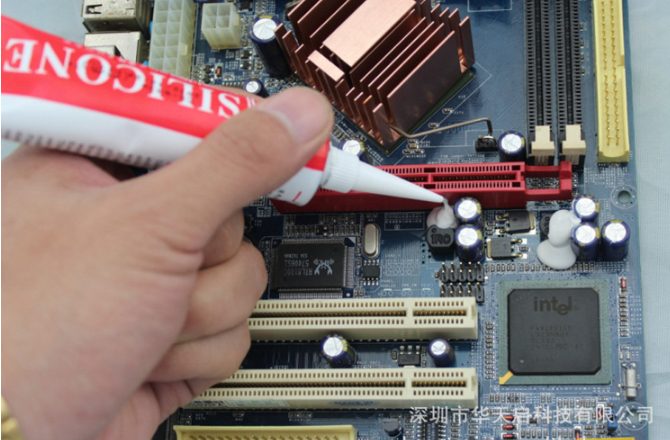

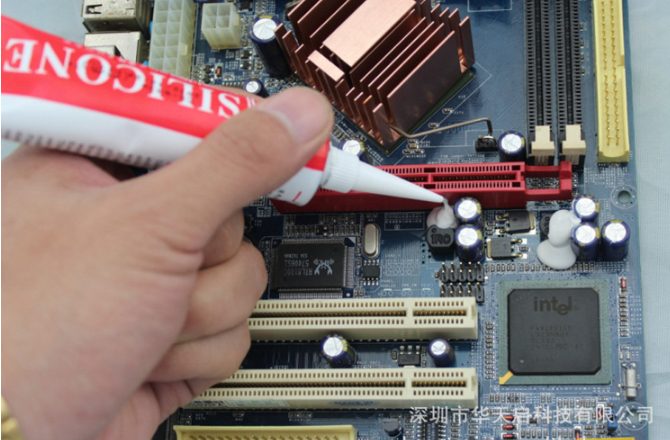

* clean the surface to be constructed, cut off the top of the sharp mouth and seal it according to the dosage, install it on the packaging mouth, apply it on the construction surface, and put it in the air. The surface of the product can lose its adhesion (surface dry) within 10-30 minutes at room temperature, and fully cure within 8-24 hours. The heating of the product can not obviously change its curing speed.

* Unused rubber materials shall be sealed for storage. The storage period is 6 months (25 ℃).

* this product is not dangerous, but it is not allowed to enter or eyes.

* transportation: no domestic (cn-gb), International (IMO, IATA, UN) regulations. Non dangerous goods.

Cs-875 one component room temperature curing silicone rubber has the following characteristics:

* this product is a single component organosilicon compound, and its color is white and half flowing.

* this product has good high and low temperature resistance, anti-seismic, anti corona, anti leakage insulation, corrosion resistance, weather resistance and other characteristics. After curing, the colloid can be used in a wide temperature range (- 50-200 ℃).

* no shrinkage during curing, good waterproof, moisture-proof and insulation performance.

* meet the requirements of EU ROHS directive.

Official website of mobile phone

Official website of mobile phone WeChat public address

WeChat public address